Our Company

In 1926, Hugo Kühnemund, then an authorized officer at a lighting manufacturer, founded Kühnemund and initially produced lighting accessories (wall arms, connecting parts) made of metal for his former employer. Soon, other lighting manufacturers joined as customers. By 1930, the first hot-dip galvanizing plant for surface treatment was established.

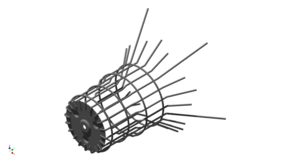

In 1938, Rudolf Kühnemund took over the management of the company and further expanded production. After World War II, the site in Thuringia could no longer be maintained due to political and economic circumstances, and the company relocated to Hamm am Rhein in 1945. Once production was re-established, the business with protective light baskets was expanded.

In 1980, Klaus and Rudolf Jr. Kühnemund assumed management. In addition to electroplating, powder coating was introduced, the first CNC wire forming machines were purchased, and various welding processes became standard. In 1983, Rudolf Kühnemund KG was renamed Rudolf Kühnemund GmbH, which remains the company’s legal form today.

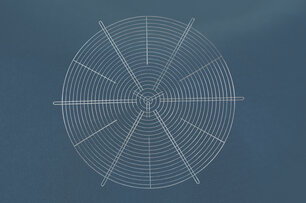

By 1987, protective grids and motor brackets for the fan industry were added. In 1990, production of cable support systems and trays began. Since 1994, bent parts have been manufactured on 3D bending and winding centers. Modern ERP and PPS software has been introduced in administration, and processes are increasingly digitalized. From 2003 onwards, 6-axis robots were integrated to further streamline production.

Quality Policy

Meeting our customers’ needs and the expectations that arise from them is the foundation of our quality strategy. At the heart of everything we do lies the fulfillment of the trust placed in us, with the ultimate goal of complete customer satisfaction.

We take full responsibility for the successful implementation of this mission.

Our actions are guided by responsibility, commitment, integrity, and honesty. Continuous striving for perfection, the involvement of all employees in ongoing improvement processes, and a purposeful quality management system are the cornerstones of achieving our objectives.

Ongoing training and development, careful use of natural resources, and support for community-oriented activities reflect our sense of social responsibility. In this way, we meet the demands of the future with thoughtful, sustainable, and high-quality growth.