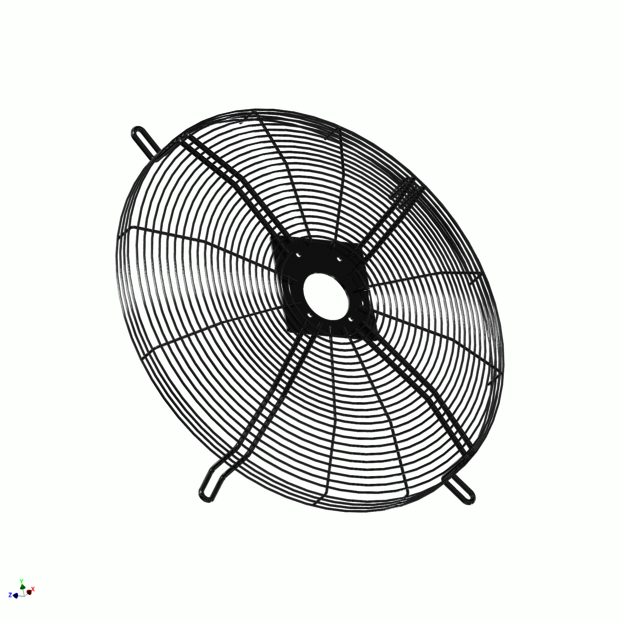

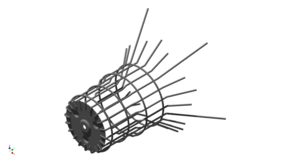

Wire Guards

We manufacture wire guards according to customer specifications. Using our CAD Inventor system, we support you in finding the optimal individual solution for your project.

In our DIN ISO 9001 certified facility, we process only high-quality raw materials such as iron wire, stainless steel wire, and brass wire. The individual components of the wire guards are precisely formed on CNC-controlled machines and subsequently welded in robotic cells.

The templates and tools for the wire guards are manufactured in our in-house workshop. For surface finishing, we offer galvanizing, powder coating, pickling, and electropolishing.

Wire Guards – Application

Our wire guards are used in a wide range of applications, for example:

-

Wire guards with integrated hydraulic motor mounts in construction machinery

-

Wire guards with mounts for heavy electric motors in generators and compressors

-

Lightweight wire guards serving as finger protection on fans and coolers

-

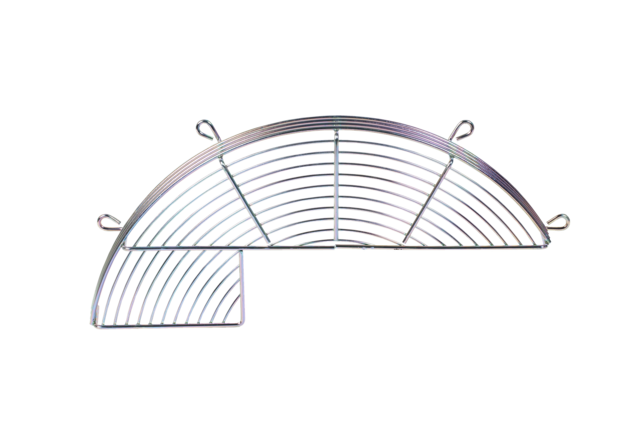

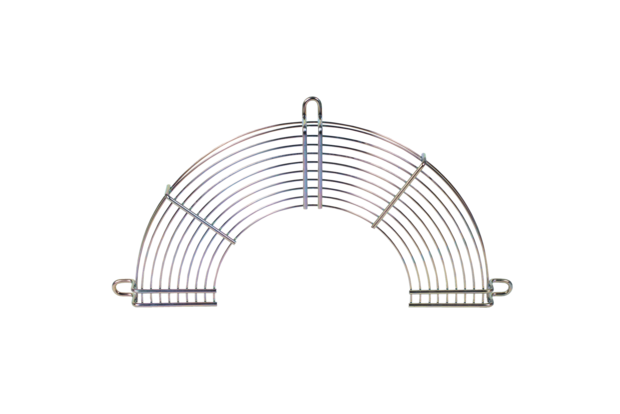

Two-part wire guard designs

Wire guards manufactured for the construction machinery industry are characterized by excellent vibration resistance and are optimally protected against corrosion through functional galvanizing.

In addition, our wire guards can be coated in our powder coating facility with a charged polyester mixture and cured in an oven at 200 °C. The result is a smooth surface, either glossy or matte, depending on color preference.

With a coating thickness of 80 µm, this finish is significantly thicker than conventional galvanizing (standard 12 µm) and therefore provides enhanced corrosion protection.